Our special containers offer customized solutions for transporting highly sensitive or heavy components and products. From hazardous goods such as airbags, to heavy components made from metal, to components for photovoltaic systems – our special packaging ensures they are transported safely.

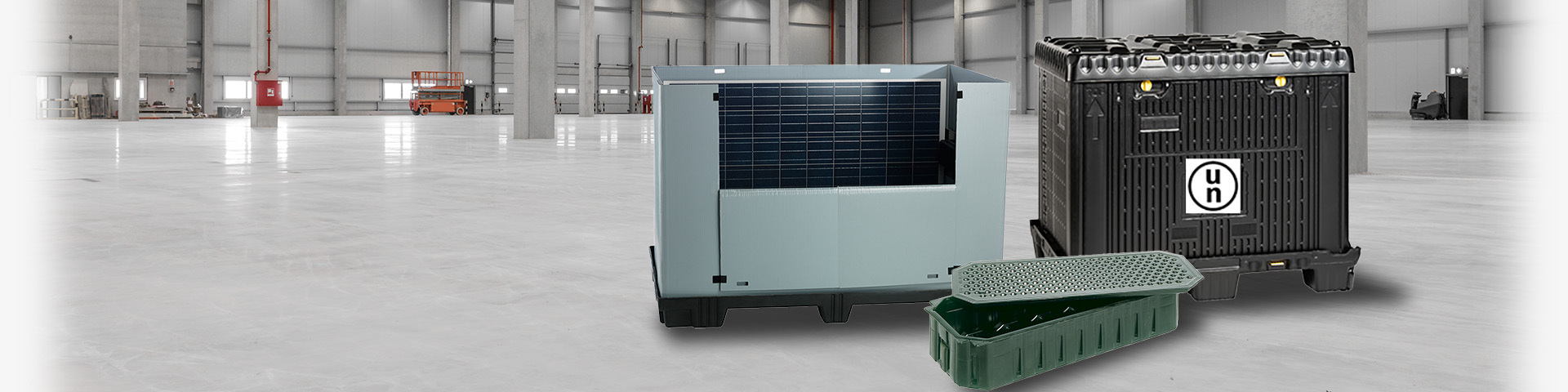

Our special containers are ideal for transporting goods for which normal load carriers are not sufficient. Our MegaPack large load carriers and twin-sheet transport containers provide the basis for this. They are intended for the transfer of sensitive cargo such as solar cells, airbags or batteries and are individually tailored to the goods to be transported. Our range of special containers covers three different areas: Hazardous goods packaging, heavy-duty containers and solar packaging.

We offer BAM- and UN-certified large load carriers for hazardous goods. The transport of airbags for the automotive industry is one popular field of application for this type of packaging. Battery packaging for lithium-ion batteries, as found in electric vehicles, is also an important part of our repertoire. Besides the automotive industry and its suppliers, we also offer solutions for various other industries such as aviation and the electronics industry.

The special containers for hazardous goods are based on the MegaPack JUMBO and JUMBO X large load carriers, which are correspondingly certified for hazardous goods (BAM + UN) and comply with the legal requirements for transport routes: ADR, IMDG Code, ICAO-TI, RID. The hazardous goods containers come in sizes from 1140 x 595 to 2250 x 1140 and a maximum payload of 850 kg and load of 2000 kg.

Our heavy-duty containers are particularly stable transport containers for heavy components made of metal – for example engine components or transmission parts for the automotive industry. Other applications for the special containers include transporting components for large machines, commercial vehicles or large vehicles such as trains or aircraft. The heavy-duty containers are individually designed for the goods being transported. This is done using a special floor construction: The bottom inside each heavy-duty container is formed to ensure the component fits securely. The bottom of the floor is fitted with a drawn-in floor contour, saving a few millimeters in height. The advantage: A significantly higher packing density than injection-molded containers. A further advantage is that the container is produced in one piece together with the shaped component holder. No further inlays are required. The containers are made of HDPE and have a maximum load capacity of up to 800 kg. Corresponding metal interlayers and carrier systems that allow stable stacking for transport are also no problem.

We offer individual solar containers for transporting several solar modules for photovoltaic systems in one packaging unit. These special containers are also based on our well-known MegaPack large load carriers – mainly MegaPack XXL and MegaPack GAMMA. They are equipped with a precisely fitting interior that holds the solar modules in place inside the container. This is done using a partition with plastic guide rails that are adjusted to the dimensions of the solar modules. The guide rails protect the modules from vibrations during transport and make loading and unloading easier. The sturdy sleeve with optional removable side panel protects the solar modules from damage or weather. Like all load carriers in the MegaPack series, our solar containers can be reduced in volume for empty transport or storage. Sizes possible from 1200 x 800 to 2250 x 1495 mm.

We have been renowned for our expertise in reusable load carriers, workpiece carriers and other packaging solutions for over 50 years. We provide you with the right basis for transporting your goods – including hazardous, sensitive or heavy goods. Benefit from our know-how and put your trust in our special containers. If you have any questions about our hazardous goods packaging, heavy-duty containers or solar containers, our sales team is always at your side. Simply fill out the contact form, send us an email or give us a ring.