Parts that run through automated production and storage processes demand individual transport and packaging solutions that have been adapted to the respective conveyor technology. For our customers, we thus develop special workpiece carrier and load carrier systems that have been perfectly adapted to the conditions arising during automated handling. Contour-precise nests that have been adjusted to the product provide the parts with a safe hold, while high form precision to a tenth of a millimeter guarantees the dimensional stability required for automatic equipping and removal. A clever arrangement of the parts also guarantees a high load density and the stackability of the load carriers for an optimum utilization of the transport and storage volume.

23%

faster processes.

Thanks to Söhner workpiece carriers designed specifically to fit the cylinder heads.

Labeling using color strips or arrows indicating the direction of running prevent incorrect insertion.

Special reference contours guarantee that the position of the workpiece carrier is mechanically recognized.

The dome is used to check the position and fix the workpiece carrier into place during handling.

A perimeter groove is required to lift and lower the workpiece carrier.

Simplifies the handling of the workpiece carrier.

Labels, document pouches and other code carriers for identification can be attached without a problem.

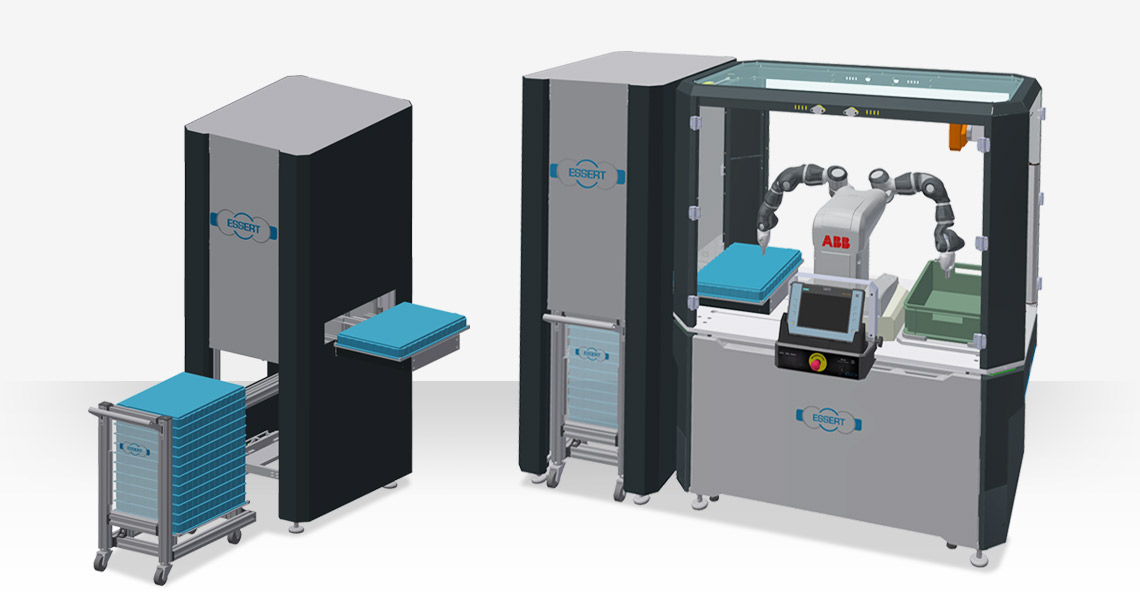

Fully integrable and dynamically configurable, the tray stacker from ESSERT Robotics allows automatic handling and processing of workpiece carriers while saving maximum space.

Reducing manufacturing costs through automated workpiece feeding without the assistance of employees.

Effortless adaptation to workpiece carrier shapes guarantee flexible and versatile use of the tray stacker.

Increase in autonomy time due to easy expansion of the pre-storage capacity.